Video

© 1999 Soren Krohn

Click on image to restart video

Testing

Wind Turbine Rotor Blades

Fatigue

Testing of Rotor Blades

![]() The

video to the left (122 K) shows how a 32 m rotor blade is fatigue

tested by being bent cyclically in a flapwise direction for 5

million full cycles. A full flapwise test thus takes about three

months.

The

video to the left (122 K) shows how a 32 m rotor blade is fatigue

tested by being bent cyclically in a flapwise direction for 5

million full cycles. A full flapwise test thus takes about three

months.

![]() If you look closely to the left you can see

another (shorter) rotor blade being bent cyclically in an edgewise

(chordwise) direction.

If you look closely to the left you can see

another (shorter) rotor blade being bent cyclically in an edgewise

(chordwise) direction.

![]() In both cases the blades are bent using a

cycle close to the natural frequency of the blade.

In both cases the blades are bent using a

cycle close to the natural frequency of the blade.

![]() The natural frequency is the frequency with

which the blade will oscillate back and forth, if you push it

once in a certain direction and let go. The natural frequencies

are different in the flapwise and edgewise direction: The blade

tends to be much stiffer in the edgewise direction, thus it has

a higher natural frequency for edgewise bending.

The natural frequency is the frequency with

which the blade will oscillate back and forth, if you push it

once in a certain direction and let go. The natural frequencies

are different in the flapwise and edgewise direction: The blade

tends to be much stiffer in the edgewise direction, thus it has

a higher natural frequency for edgewise bending.

![]() Each blade is set in motion by an electric

motor mounted on the blade which swings a weight up and down.

The foundations which carry the blade socket have to be very

solid: The foundation for the large blade socket consists of

2,000 tonnes of concrete.

Each blade is set in motion by an electric

motor mounted on the blade which swings a weight up and down.

The foundations which carry the blade socket have to be very

solid: The foundation for the large blade socket consists of

2,000 tonnes of concrete.

![]() This video was shot at the rotor blade test

facility of the Risoe National Laboratory Sparkær Test

Centre in Jutland, Denmark. (Type approval requirements for rotor

blades are very strict in Denmark, requiring physical testing

of rotor blades for both fatigue properties (fatigue testing)

and strength properties (static testing). Other countries usually

have less stringent requirements for type approval of rotor blades).

This video was shot at the rotor blade test

facility of the Risoe National Laboratory Sparkær Test

Centre in Jutland, Denmark. (Type approval requirements for rotor

blades are very strict in Denmark, requiring physical testing

of rotor blades for both fatigue properties (fatigue testing)

and strength properties (static testing). Other countries usually

have less stringent requirements for type approval of rotor blades).

Rotor

Blade Materials

Rotor blades are usually made using a matrix of fibre

glass mats which are impregnated with a material such as polyester

(GRP = Glass fibre reinforced polyester). The polyester is hardened

after it has impregnated the fibre glass. Epoxy may be used instead

of polyester. Likewise the basic matrix may be made wholly or

partially from carbon fibre, which is a lighter, but costlier

material with high strength. Wood-epoxy laminates are also being

used for large rotor blades.

The

Purpose of Testing Rotor Blades

The purpose of rotor blade testing is to verify that laminations

in the blade are, safe, i.e. that the layers of the rotor blade

do not separate (delamination). Also, the test verifies that

the fibres do not break under repeated stress.

Photograph

© 1999 Soren Krohn

Measuring

Strains

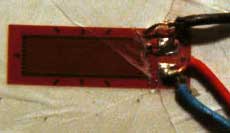

![]() Strain gauges, (i.e. flat electrical resistors

which are glued on to the surface of the rotor blades being tested),

are used to measure very accurately the bending and stretching

of the rotor blades.

Strain gauges, (i.e. flat electrical resistors

which are glued on to the surface of the rotor blades being tested),

are used to measure very accurately the bending and stretching

of the rotor blades.

Photograph

© 1999 Soren Krohn

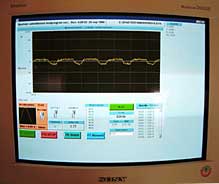

Monitoring Fatigue Testing

Infrared

Inspection (Thermography)

Infrared cameras are used to reveal local build-up of heat in

the blade. This may either indicate an area with structural

dampening, i.e. an area where the blade designer has deliberately

laid out fibres which convert the bending energy into heat in

order to stabilise the blade, or it may indicate an area of delamination

or an area which is moving toward the breaking point for the

fibres.

Modal

Forms of Rotor Blade Vibrations

From the year 2000 blade testing (in Denmark) also includes a

verification of the different modal forms of vibration

of each blade. This is done using a special type of equipment

which excites the blade vibrations at different frequencies and

in different directions.

![]() Different modal forms of oscillation are

also known when building musical instruments: A string on a violin

may oscillate with is basic tone, i.e. the centre of the

string moving up and down, but it will usually also oscillate

with the first overtone or first harmonic, with two centres

of oscillation located at a distance of 1/4 from each end of

the string, moving at twice the frequency of the basic tone or

natural frequency.

Different modal forms of oscillation are

also known when building musical instruments: A string on a violin

may oscillate with is basic tone, i.e. the centre of the

string moving up and down, but it will usually also oscillate

with the first overtone or first harmonic, with two centres

of oscillation located at a distance of 1/4 from each end of

the string, moving at twice the frequency of the basic tone or

natural frequency.

![]() The reason why manufacturers of wind turbines

are interested in studying and verifying the various forms of

vibration frequencies in rotor blades, is that they have to make

sure that the turbine on which the blade is to be mounted does

not have some of the same natural frequencies as the rotor blade.

Otherwise, a resonance may occur in the whole structure

of the turbine, leading to undampened vibrations which

may eventually wreck the whole wind turbine. We will return to

this issue on the page on structural

dynamics in the design section later in this guided tour.

The reason why manufacturers of wind turbines

are interested in studying and verifying the various forms of

vibration frequencies in rotor blades, is that they have to make

sure that the turbine on which the blade is to be mounted does

not have some of the same natural frequencies as the rotor blade.

Otherwise, a resonance may occur in the whole structure

of the turbine, leading to undampened vibrations which

may eventually wreck the whole wind turbine. We will return to

this issue on the page on structural

dynamics in the design section later in this guided tour.

Static

Testing of Rotor Blades

Rotor blades are also tested for strength (and thus

their ability to withstand extreme loads) by being bent once

with a very large force. This test is made after the blades has

been subject to fatigue testing, in order to verify the strength

for a blade which has been in operation for a substantial amount

of time.

![]()

|

Back | Home

| Forward |

© Copyright 2000 Soren Krohn

Updated 16 August 2000

http://www.windpower.org/tour/manu/bladtest.htm